| |

TCO or TCO2

11 May 2018 • Ype Wijnia and John de Croon

policy development

|

630 persons

like this column |

In last week's column we showed that sustainability will not succeed on your own: nobody has enough space for solar panels to reduce CO2 emissions to zero. In terms of the asset life cycle, however, we only looked at the operation phase. In this week's column we look a little broader and take the entire life cycle into consideration.

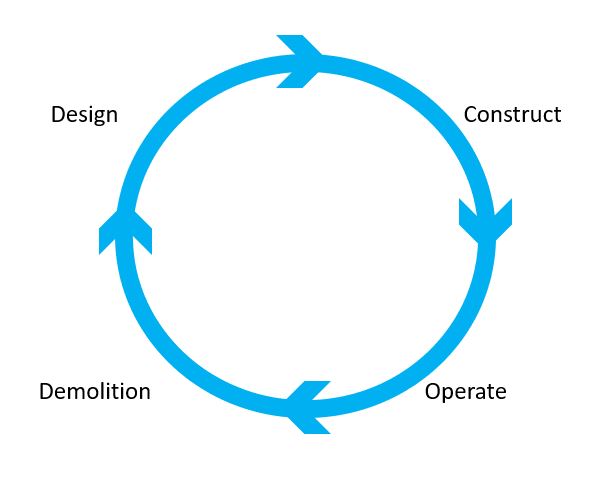

In an economic life cycle analysis (life cycle costing) you determine the total costs of a solution from cradle to grave, the so-called Total Cost of Ownership (TCO). Now the costs are not that interesting in themselves, it is after all what you achieve. For this reason, a TCO is often calculated back to costs per unit of production (production assets) or costs per operating year (infrastructures and the like). With such an analysis, you can make for example visible that it makes sense to initially spend a little more money, because it will save a lot of life[1].  When building a new manure digester (corrosive environment!) you can choose to use cheap steel. However, it quickly rusts with high recovery costs as a result (actually experienced). You can also choose a higher quality material or to coat the steel (both initially more expensive), but they last much longer. For sustainability you can make a similar consideration, which is called Life Cycle Analysis (LCA)[2]. In an official LCA, all environmental impacts are taken into account (including exhaustion, biodiversity damage, toxicity and so on), but for simplicity we keep it limited to CO2 in this column. What you then can make visible with the LCA is whether the measures you take to become more sustainable also have a real effect, and for example how long it takes before the investment in sustainability is recouped. This ecological payback period can be very different from the economic one. This is because not every euro of material produces the same amount of CO2 (or vice versa, not every kilogram of CO2 is equally expensive). By burning coal you get the most CO2 per euro, while services produce much less per euro. This can be very relevant for climate change. With current technology, every production of goods (including sustainable solutions) results in CO2. If the payback period is long, you will only bring more CO2 into the atmosphere in the short term. Only when your own production costs are earned back, can you make new sustainable products with the remainder. In addition to last week's column, we will consider the entire life cycle for a number of individual solutions from that column. When building a new manure digester (corrosive environment!) you can choose to use cheap steel. However, it quickly rusts with high recovery costs as a result (actually experienced). You can also choose a higher quality material or to coat the steel (both initially more expensive), but they last much longer. For sustainability you can make a similar consideration, which is called Life Cycle Analysis (LCA)[2]. In an official LCA, all environmental impacts are taken into account (including exhaustion, biodiversity damage, toxicity and so on), but for simplicity we keep it limited to CO2 in this column. What you then can make visible with the LCA is whether the measures you take to become more sustainable also have a real effect, and for example how long it takes before the investment in sustainability is recouped. This ecological payback period can be very different from the economic one. This is because not every euro of material produces the same amount of CO2 (or vice versa, not every kilogram of CO2 is equally expensive). By burning coal you get the most CO2 per euro, while services produce much less per euro. This can be very relevant for climate change. With current technology, every production of goods (including sustainable solutions) results in CO2. If the payback period is long, you will only bring more CO2 into the atmosphere in the short term. Only when your own production costs are earned back, can you make new sustainable products with the remainder. In addition to last week's column, we will consider the entire life cycle for a number of individual solutions from that column.

We start with the options for covering the current energy consumption. As an individual you have the option to install solar panels. There have been rumors for a long time about solar panels that their production costs more than what they will ever save[3]. In the beginning, when it was still experimental technology, that was perhaps true. But even if you are counting with a fairly pessimistic footprint of 20 kg CO2 emissions per kg of solar panel, a modern panel (which weighs about 18 kg for 300 Wp[4]) will still be reclaimed in about 2 years[5]. Wind turbines do even better, they have a payback period of about half a year[6].

The second solution was heating. A heat pump is much more energy-efficient, but is economically just or not profitable. Fortunately, for the CO2 effect it is much clearer. Suppose you save 1500 m3 of natural gas per year with the heat pump, which corresponds to 2700 kg of CO2. You can invest 27000 kg over the 10-year lifespan, even 54000 kg in 20 years. With 20 kg of CO2 emissions per kg[7], this amounts to an installation with an extra weight of 1350 to 2700 kg, or the weight of a large passenger car. That seems a bit much, with about 200 kilos you should still be ready[8]. Here too the energetic payback time is less than 10% of the lifetime.

Unfortunately, this is a different story for cars. As we showed in the previous column, the energy consumption of the car is comparable to that of a heater. The maximum saving is therefore comparable and therefore also the maximum weight of the installation. That weight of a car is unfortunately in the same order of magnitude as the maximum weight of the heater. Now it deals with the extra weight, but when the electric car has to be a complete alternative to the fossil solution, that extra weight because of the batteries can be 500 kg more, based on 1 kg per km range. The energetic business case then becomes very thin. Only when you drive a lot more kilometers with the car, it could be attractive. There are also opportunities for this. Most cars only last about 15 years, with an average of 15000 km per year. So the total utilization is only 225.000 km. From our own experience we know that cars (if properly maintained of course) easily go double. Now you cannot stretch those 15 years a lot, but the mileage can be stretched for example by sharing the car. That also saves a footprint of parked cars.

What could also work is a good recycling of the car, then you spread the environmental burden for the production of the car across more kilometers. Only, the raw materials provide only a limited part of the CO2 burden (see footnote number 4), and that is all that you save. The fact that recycling of materials is not evidently good for the environment is also apparent from the many discussions that take place around collection. One report shows for example that pottery coffee cups are the best, while other studies show that disposable cups have the least environmental effect. This contradiction in data was encountered in the research for this column. Even on the CO2 impact of simple building materials, the experts do not seem to be able to agree, we sometimes found a factor 10 difference. For the real "no brainers" (with a payback time in the order of 10% of the life time) that does not matter that much, they remain positive in a worst case calculation. But it is difficult for borderline cases. Or do we still kick the trap of the decision makers: if the alternatives do not matter much then it does not matter what you choose, a better method does not give a better answer[9]. Our feeling at this moment says that a factor 10 is relevant, then you can make a radically different choice. Time for a standardized TCO2.

[1] http://www.assetresolutions.nl/en/column/life-cycle-costing-is-required-for-asset-management

[2] Handreiking bij stap één in LCA: Doel & Scope. Agentschap NL, Ministerie van Economische Zaken, Landbouw en Innovatie

[3] https://www.nrc.nl/nieuws/2016/10/26/zonnecellen-leveren-echt-wel-meer-energie-op-dan-ze-kosten-4996988-a1528578

[4] 360 kg CO2 production cost, 300 kWh per year yield with 0,6 kg CO2 per kWh

[5] http://www.changemagazine.nl/klimaatkennis/energie/zonnepanelen-duurzaam-of-toch-vervuilend

[6] http://cop15.ecn.nl/uploads/media/factsheet_wind.pdf

[7] This figure is widely used for extraction, production, transport and installation. For the solar panels, it also completely correct. What only wriggles with us (but that is probably our own stupidity), is that in our opinion the production of raw materials such as aluminum and copper is the most harmful. If you make calculations, it appears that only a part of this 20 kg is covered. The chain behind it apparently also gives a big load. That is bad news for all recycling initiatives and the circular economy.

[8] The heat pump for heating water for 1 of us weighs about 100 kg, these are slightly larger

[9] http://www.assetresolutions.nl/en/column/paradox-of-choice

John de Croon and Ype Wijnia are partner at AssetResolutions BV, a company they co-founded. Periodically they give their vision on an aspect of asset management in a column. The columns are published on the website of AssetResolutions, http://www.assetresolutions.nl/en/column

<< back to overview

|