| |

The right quality

14 November 2014 • Ype Wijnia

asset management strategie, risk management, policy development, planning

Two weeks ago, the 9th World Conference on Engineering Asset Management was held in South Africa. For us it was a very successful conference. That is because we received the 'best paper award' for the description of our reference model for asset management processes for infrastructures. With the reference model it is relatively easy to meet the requirements of ISO 55001. However, put that aside. What I wanted to talk about is the enormous energy that emanates from a conference of more than 200 participants who are all working to further develop asset management. The entries ranged from theoretical treatises on how it should be (to which our paper also belongs) to case studies from practice which show how much improvement was achieved with asset management. In none of the stories asset management was put down as a magical tool with which everything was much times better at once. On the contrary, everywhere came across that mainly a systematic and structured approach brought the improvement. And do not give up too quickly definitely was a key success factor.

A very impressive presentation in this regard was the tutorial of John Woodhouse. For those who do not know that name, it is one of the pioneers in the field and one of the initiators for the development of PAS55, the unofficial asset management standard. In his story he took examples from the oil industry in the North Sea in the late eighties, which was then plagued by a crisis. Oil prices had plummeted and due to the accident on the Piper Alpha with many deaths the whole industry was to collapse. By changing the way of working from a compliance culture (we have met all the requirements so it's OK) to a risk culture (we understand what can go wrong and we do everything in our power to manage that) they were capable to reinvent the whole industry. The safety improved with very large steps, at the same time the cost of the platforms decreased and production increased. Although each asset management diehard knows the figures, they remain impressive. Reduction of the safety incidents over 75%, a reduction in the cost per unit of more than 90%, and an increase in the availability of the platforms from 80% to 99%. Even with these improvements achieved one does not rest. There is still an ongoing effort going to see where it can be safer, better, cheaper.

A striking feature of all the stories was that there was not too much looking back, in the sense that it was suggested that what was previously done was not good and what is now being done is well. It was more the other way around, what they did today was not perfect but they did everything possible to make tomorrow better. With that mind-set what you did in the past is not so relevant, since you can do nothing to change that. It is about the now and the future, you still can influence it. Speaking of influence, asset management is all about doing everything in your power to improve, not too quickly recall that it is another's problem. Asset management is working as a small business in a large organization where everything you do and don’t is a conscious choice.

After such inspiring days practice sometimes is a bit of a disappointment. If you're talking about the improvement opportunities out there, the first reaction often is the question whether one is currently not now doing well. Or they do not even ask the question, but posts instead that its own assets are so unique that the success stories can really not be repeated here. This is then often followed by the remark that one actually already executes asset management a long time and that it really cannot get better.

Although you sometimes tend to get respond like "AWAKE BUNCH OF NAVEL-GAZERS, THESE RESULTS ARE ACHIEVED OVER THE WORLD IN ALL KIND OF SECTORS AND THERE IS REALLY NO REASON TO BELIEVE THAT IT WOULD NOT WORK HERE", we as professionals of course have a neater answer. We therefore again explain it once.

Asset management is, put simply, getting the maximum net value[1] from the stuff. In normal language it is called optimization, but since this concept is no longer used throughout the ISO55000 standard we adapt ourselves to it. Value is not necessarily just financial, it can also be safety, quality, sustainability, justice and so on go. What aspects are relevant is not determined by the asset manager, but by the asset owner. Stakeholders should be taken into account which may affect the value. You as manager can have the opinion the roar of the machines is a lovely sound, but when the neighbours complain about it you will have to do it something about it, else they can only be uncooperative. It is extremely important to realize that value is not a static concept. In the course of time insights can change in the importance of sustainability or justice, and the optimum will thus shift. In that respect Asset management is never finished, you'll always have to match it to the current context.

If the values are set (in our terminology, the business value model), the asset manager can set to work. Roughly this is possible in three directions. In the first place, you have to make sure that the correct problem is solved. Second, you must choose the right solution to that problem, and that can also be accepting the problem. Finally, you must ensure that the solution is implemented properly. This can be done for each individual issue. But the power of asset management is to a large extent also in coordination between the issues. Something may indeed be the proper solution to a problem, but that does not mean that the main problem is solved. Suppose on your way to an important appointment you are faced with a dirty car that also has an empty tank. There is time to either refuel or to wash the car, but not both. How important a clean car can be, if you do not fill it up do not you arrive at the appointment, so if you have to choose you need to refuel.

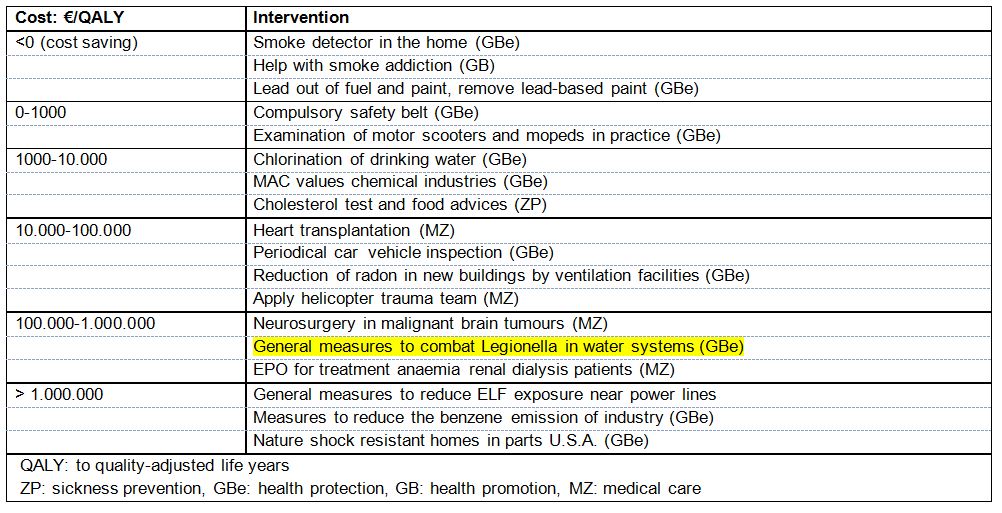

In addition to this conditional planning (something only has value when first something else is done) also efficiency can be prioritized, say the price / quality ratio. Something can have added value, but it does not fit within the available constraints because other things have more benefits. And it is precisely in this area that asset management really comes into its own, because you can not see this from problem perspective. Take for example the control of legionella. Dead ends in the waterworks need to be prevented. With a new design, you can keep this in mind, but for existing systems that quite expensive. In the RIVM report "dealing sensibly with risks"[2] a number of measures are presented, and it shows that legionella control is not the most obvious when it comes to improving public health. That is because it is quite expensive per unit effect.

Table according to “nuchter omgaan met risico’s” ("sober dealing with risks"), RIVM 2003, page 34

Also in asset management such differences in effectiveness occur. By first executing measures with the highest efficiency an enormous improvement of overall effectiveness can achieved. For example, there are 100 projects with a yield between 100 and 1 (uniformly distributed). Every project itself has a net value, so without coordination the budget allocation would be on the first come first served principle. This gives an average yield of 50. If instead the best 50 projects are chosen, this will result in an average yield of 75. Within the same budget 50% more value can be delivered. This is also the improvement that you see in practice. But to achieve that you have to ensure a systematic consideration of costs and benefits. In other words, asset management. We rest our case!

[1] Say the benefits minus costs

[2] http://www.rivm.nl/bibliotheek/rapporten/251701047.html

Ype Wijnia is partner at AssetResolutions BV, a company he co-founded with John de Croon. In turn, they give their vision on an aspect of asset management in a biweekly column. The columns are published on the website of AssetResolutions, http://www.assetresolutions.nl/en/column

<< back to overview

|